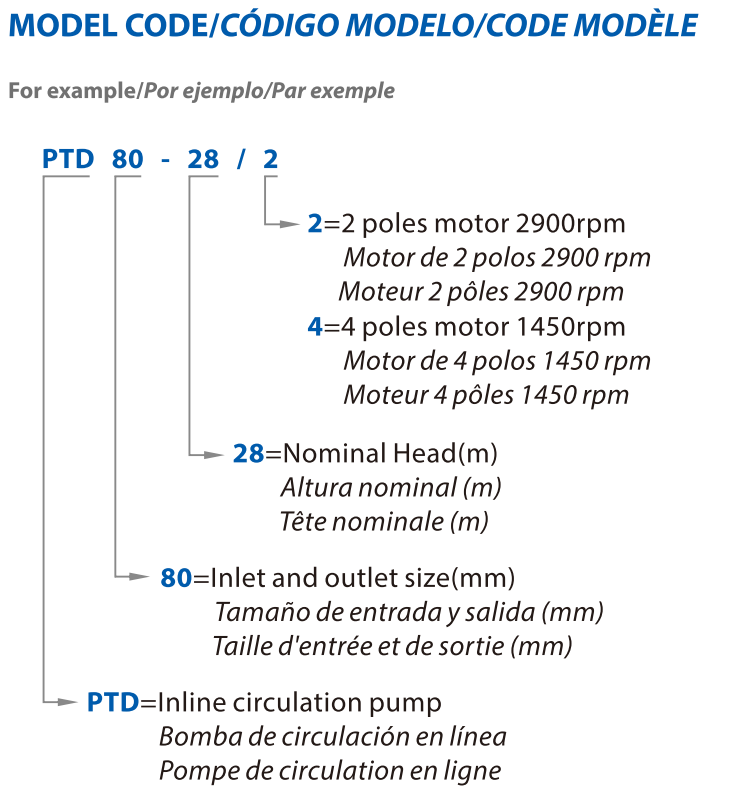

Single Stage Electric Inline Pipeline Centrifugal Pump

Product Introduction

Purity PTD inline centrifugal pump shaft is made of 304 stainless steel and 45 steel connected by friction welding technology. This innovative design ensures a strong, secure connection between the two materials, enhancing the inline water pump’s durability and resistance to wear. The shaft is cold-extruded and precision-machined using advanced processing, achieving exceptional concentricity and precision. This construction reduces operational noise and ensures smooth of inline centrifugal pump, efficient performance even under heavy use.

Both the PTD inline pump body and impeller, along with other key connecting components, are treated with an electrophoretic surface coating. This electroplating process delivers outstanding rust resistance, making the inline centrifugal pump highly reliable in challenging environments. It can endure salt spray tests lasting up to 72 hours without any signs of corrosion, ensuring long-term performance and minimal maintenance requirements.

Purity PTD inline centrifugal pump head and impeller are designed using Computational Fluid Dynamics (CFD) for hydraulic analysis and scientific optimization. This process significantly improves the hydraulic compatibility and performance of the centrifugal water pump, optimizing fluid flow and enhancing energy efficiency. The design ensures the pump operates with maximum efficiency, reducing energy consumption while maintaining high performance.

One of the key features of the PTD vertical centrifugal pumps is the independent structural design of the motor shaft and pump shaft. This design simplifies the installation, disassembly, and maintenance processes. With easy access to key components, routine maintenance can be performed quickly and efficiently, reducing downtime and operational costs.Purity inline water pump hopes to be your first choice, welcome to inquiry!

1-300x300.jpg)