PST standard centrifugal pump

Product Details

Featurw:

1. Equipped with energy-saving motors certified by national standards: The motor stator adopts high-performance cold-rolled steel strips, pure copper coils, and low temperature rise, greatly improving the working efficiency of the motor. The energy-saving effect of energy-saving motors certified by national standards is guaranteed.

2. Optimization treatment of inlet and outlet: The inlet is larger than the outlet, resulting in more sufficient water inflow and superior performance. It can also reduce the occurrence of cavitation, extend service life, and not lack strong power.

3. National standard flange interface: The entire series uses national standard PN10 flange interface, which is easy for users to install and does not need to worry about non-standard hole positions.

4. Multiple seals, improved protection capability: The junction box is sealed with leather pads, and the front and rear end frames of the motor are sealed with oil seals to enhance the overall protective performance of the machine.

Application scenario:

The products are widely used in energy metallurgy, chemical textile, Pulp and paper industry, boiler hot water pressurization, urban heating system, etc. There is an engineering team that provides specialized and integrated solutions based on actual application situations to improve the overall efficiency of the pump operation system, improve efficiency, and reduce costs.

Model Description

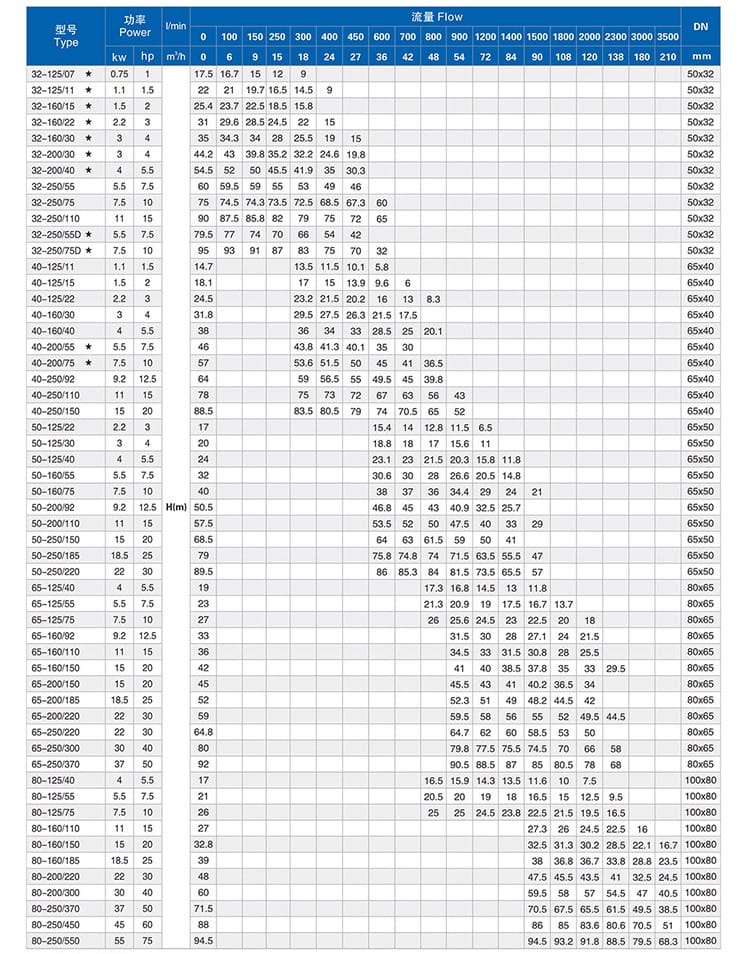

Technical Parameter

| Discharger (m3/h) | 0~600 |

| Head (m) | 0~150 |

| Power (Kw) | 0.75~160 |

| Diameter (mm) | 32~200 |

| Freq uency (Hz) | 50、60 |

| Voltage (V) | 220V、380V |

| Fluid temp (℃) | 0℃~80℃ |

| Work Press (p) | Max 1.6Mpa |

Pump structural characteristics

The pump casing size complies with EN733 regulations

Pump casing made of cast iron material, flange connection

Butt flange cast iron, in accordance with ISO28/1

Impeller: cast iron or stainless steel

Motor: Class F insulation level

IP54 protection level

Product parameters

Flange size

-300x300.jpg)