The Purity PV Vertical Multistage Jockey Pump is a hallmark of advanced engineering and innovation in the field of fluid handling systems. This pump has been meticulously designed and optimized to provide unparalleled energy efficiency, performance, and stability. Its cutting-edge features make it a preferred choice for maintaining consistent water pressure in a variety of applications. In this article, we will explore three key aspects that set the Purity PV Vertical Multistage Jockey Pump apart: its optimized hydraulic design, advanced mechanical seals, and precision laser welding technology.

Figure |Purity PV Vertical Multistage Jockey Pump

Optimized Hydraulic Design for Enhanced Efficiency

The Purity PV Vertical Multistage Jockey Pump has undergone a comprehensive upgrade in its hydraulic design, ensuring that it operates with exceptional efficiency and performance. This optimization process involves fine-tuning the pump’s internal components to reduce energy consumption and enhance overall functionality. The result is a pump that not only meets but exceeds industry standards for energy efficiency.

One of the primary benefits of this optimized hydraulic design is the significant reduction in energy consumption. The Purity PV pump is capable of maintaining consistent water pressure with less power, translating to lower operating costs and a reduced environmental footprint. This energy-saving capability has been internationally certified, providing users with confidence in the pump’s performance and sustainability.

Moreover, the enhanced efficiency of the Purity PV pump contributes to its remarkable stability. The pump can handle varying pressure demands with ease, ensuring a steady and reliable supply of water. This stability is crucial in applications where consistent water pressure is essential, such as in firefighting systems, irrigation, and industrial processes.

Advanced Mechanical Seals for Durability and Reliability

Another standout feature of the Purity PV Vertical Multistage Jockey Pump is its use of advanced mechanical seals. These seals are crafted from hard alloy and fluororubber materials, providing the pump with superior resistance to corrosion, rust, and wear. The choice of materials is critical in extending the lifespan of the pump and ensuring its reliable operation in harsh environments.

Mechanical seals play a vital role in preventing leaks and maintaining the integrity of the pump system. The hard alloy components offer excellent durability, capable of withstanding high pressures and abrasive conditions. Fluororubber, known for its chemical resistance, adds an extra layer of protection against corrosive substances commonly encountered in industrial and agricultural applications.

The combination of hard alloy and fluororubber materials in the mechanical seals ensures that the Purity PV pump remains functional and efficient over long periods. This durability reduces the need for frequent maintenance and replacements, resulting in cost savings and minimal downtime for users. Furthermore, the robust design of these seals enhances the overall reliability of the pump system, providing peace of mind to operators and end-users alike.

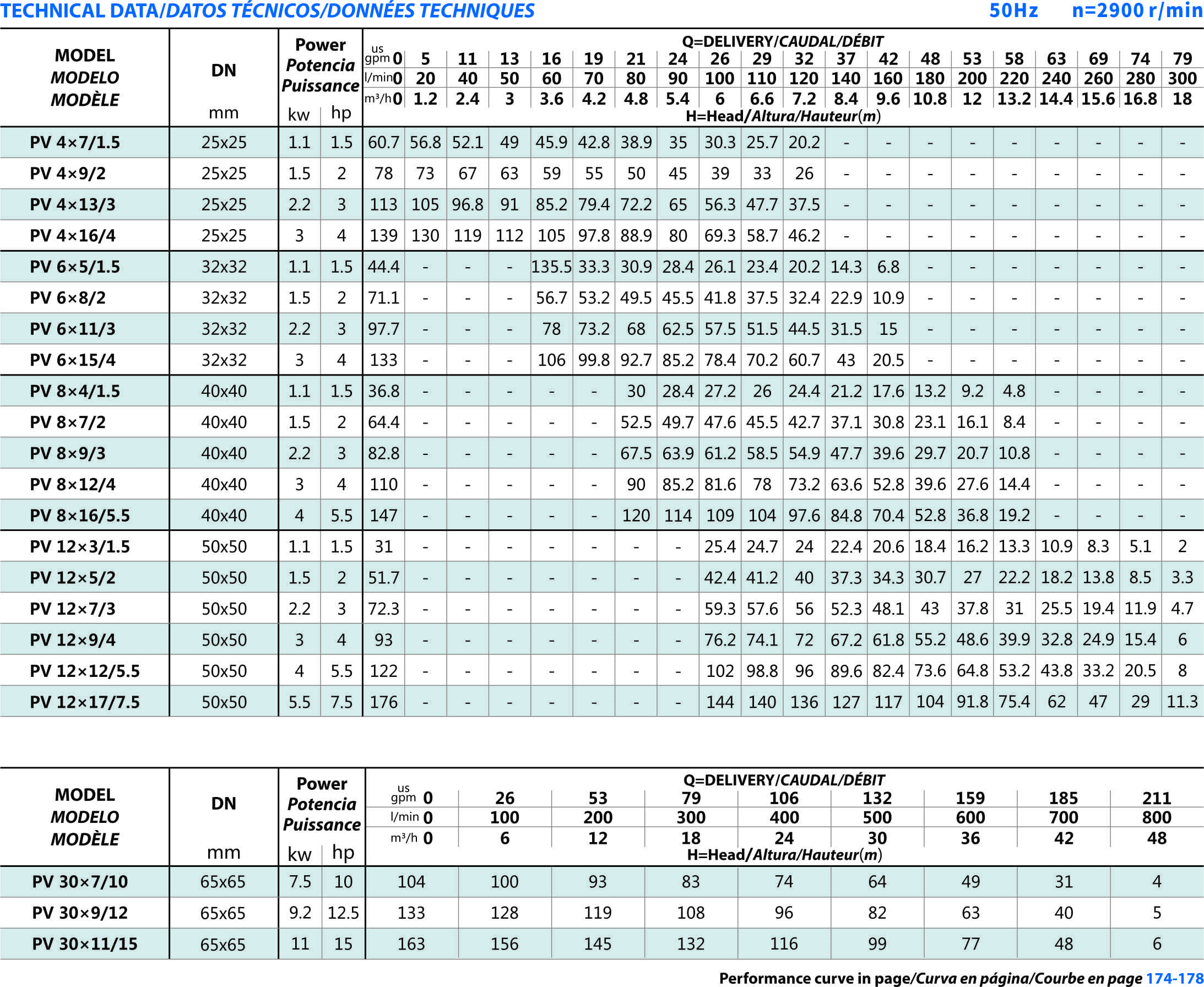

Figure |Purity PV Vertical Multistage Jockey Pump Parameter

Precision Laser Welding Technology for Structural Integrity

The manufacturing process of the Purity PV Vertical Multistage Jockey Pump incorporates precision laser welding technology. This advanced technique ensures that all welds are tight, secure, and free from defects such as leaks or weak points. The meticulous nature of laser welding provides a level of accuracy and consistency that traditional welding methods cannot match.

Laser welding involves using a highly focused laser beam to fuse materials together at a microscopic level. This process results in exceptionally strong welds that enhance the structural integrity of the pump. The precision of laser welding also allows for more complex and intricate designs, enabling the production of pumps with optimized performance characteristics.

The benefits of precision laser welding extend beyond structural integrity. By eliminating the risks of leaks and weak welds, this technology ensures that the Purity PV pump maintains its efficiency and reliability under various operating conditions. The robust construction achieved through laser welding contributes to the pump’s ability to withstand high pressures and prolonged use without compromising performance.

In addition to enhancing durability, precision laser welding also improves the overall aesthetic and finish of the pump. The smooth and uniform welds created by this process reduce the likelihood of stress points and potential failure areas, further extending the pump’s lifespan. This attention to detail in the manufacturing process reflects the commitment to quality and excellence that defines the Purity PV brand.

Conclusion

The Purity PV Vertical Multistage Jockey Pump is a testament to the advancements in pump technology and design. Through optimized hydraulic design, advanced mechanical seals, and precision laser welding technology, this pump offers unmatched energy efficiency, durability, and reliability. Its internationally certified energy-saving capabilities make it an eco-friendly choice for various applications, while its robust construction ensures long-term performance and minimal maintenance.

Whether used in firefighting systems, industrial processes, or agricultural irrigation, the Purity PV Vertical Multistage Jockey Pump provides a reliable and efficient solution for maintaining consistent water pressure. Its innovative features and superior engineering make it a valuable asset in any fluid handling system, delivering exceptional performance and peace of mind to users worldwide.

Post time: Jun-25-2024