Fire fighting systems rely on reliable and efficient pumps to ensure that water can be delivered at the required pressure to extinguish fires. Among the various pump types available, horizontal and vertical fire pumps are commonly used in firefighting applications. Each type has unique characteristics that make it suitable for different environments and requirements. Here is a detailed comparison of these two types of fire pumps, focusing on their design, space requirements, installation, flow capacity, maintenance, and drive types.

Figure| Purity Vertical Fire Pump PVT/PVS

Figure| Purity Vertical Fire Pump PVT/PVS

1.Design

Horizontal Fire Pump: Horizontal centrifugal fire pumps are characterized by their horizontal shaft orientation. In these pumps, the impeller rotates within a casing that is aligned horizontally. This design is straightforward and allows for easy access to internal components. The horizontal configuration is commonly used in larger facilities where space is less of an issue.

Vertical Fire Pump: vertical centrifugal fire pumps feature a vertical shaft orientation. The impeller is suspended in a vertical casing, which makes these pumps more compact. The vertical design is particularly advantageous in environments where space is limited, such as offshore platforms or densely packed industrial sites.

2.Space Requirements

Horizontal Fire Pump: Horizontal pumps generally require more installation space due to their larger footprint. The horizontal orientation demands ample room for both the pump and associated components, such as the motor and piping. This configuration is suitable for installations where space is not a constraint and allows for more straightforward access during operation and maintenance.

Vertical Fire Pump: Vertical pumps are designed to be more compact, occupying less floor space. Their vertical design makes them ideal for applications where space is at a premium. For example, vertical fire pumps are often used in high-rise buildings or offshore platforms where horizontal space is limited but vertical space is available.

3.Installation Requirements

Horizontal Fire Pump: The installation of horizontal fire pump can be more complex. The pump, piping, and motor must be carefully aligned to ensure proper operation. The need for precise alignment can make the installation process more labor-intensive, particularly in confined or difficult-to-access areas.

Vertical Fire Pump: Vertical fire pumps are easier to install due to their inline design. They can be mounted similarly to valves in a pipeline system, allowing for simpler and more efficient installation. The vertical configuration minimizes the complexity of aligning components, making the installation process quicker and less cumbersome.

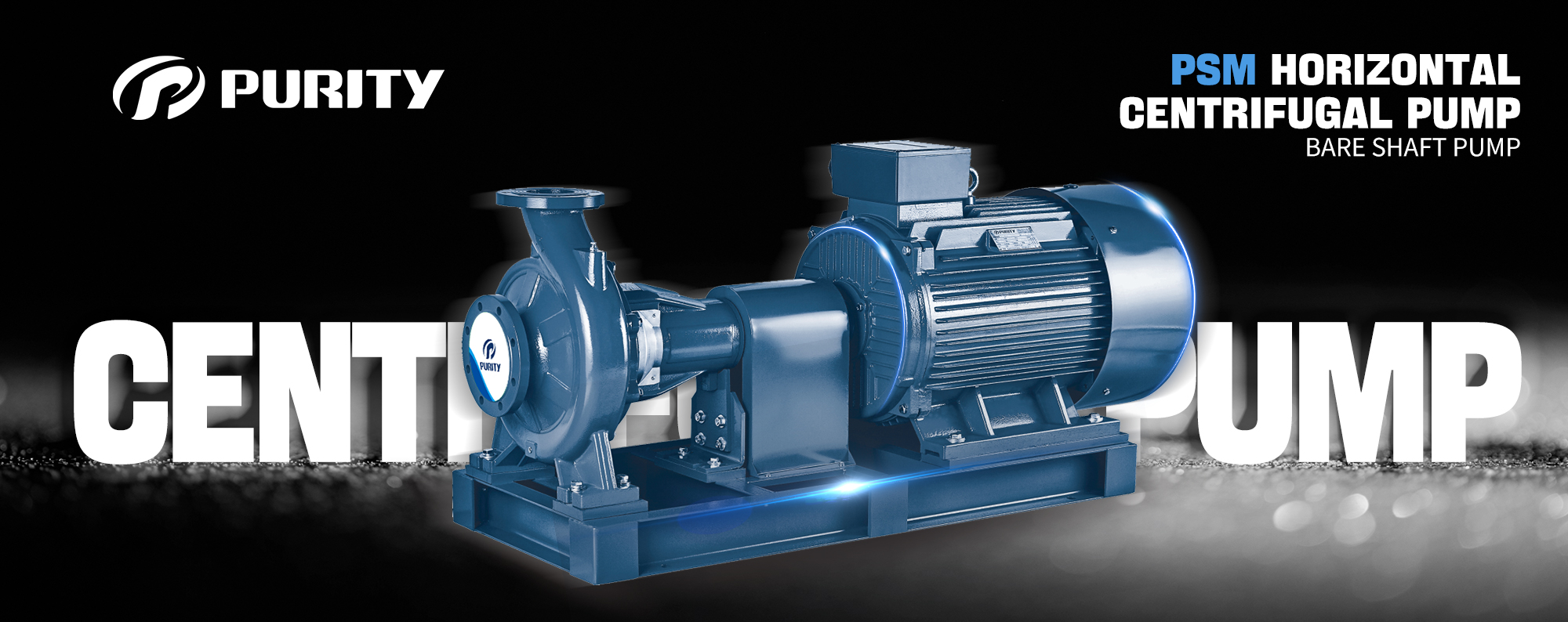

Figure| Purity Horizontal Fire Pump PSM

Figure| Purity Horizontal Fire Pump PSM

4.Flow Capacity

Horizontal Fire Pump: Horizontal fire pumps are capable of handling higher flow rates compared to their vertical counterparts. This makes them suitable for large-scale applications that require substantial water delivery, such as in large industrial facilities or extensive firefighting systems.

Vertical Fire Pump: Vertical fire pumps are generally better suited for applications with lower flow requirements. Their design is optimized for situations where the demand for water is not as high, making them ideal for smaller or more specialized fire protection systems.

5.Drive Types

Horizontal Fire Pump: Horizontal fire pump can be driven by various types of motors and engines, including electric motors, diesel engines, and gearboxes. This versatility allows for flexibility in selecting the most appropriate drive system based on the application’s power requirements and operational conditions.

Vertical Fire Pump: Vertical fire pumps are typically driven by electric motors. The vertical design aligns well with electric motor drives, offering a compact and efficient solution for fire pump applications. This drive system is often preferred in settings where electric power is readily available.

6.Maintenance

Horizontal Fire Pump: Maintenance of horizontal fire pumps tends to be easier due to their more accessible design. The horizontal orientation allows for better accessibility to the pump’s internal components, reducing the need for extensive disassembly. This ease of access can simplify routine maintenance and repairs, making these pumps a practical choice for environments where regular maintenance is required.

Vertical Fire Pump: Vertical fire pumps can be more challenging to maintain because their components are less accessible. The vertical orientation can restrict access to certain parts, potentially making maintenance tasks more difficult and time-consuming. However, their design minimizes the need for frequent maintenance compared to some other types of pumps.

Conclusion

Choosing between horizontal and vertical fire pumps involves considering several factors, including space constraints, flow requirements, installation complexity, and maintenance needs. Horizontal fire pumps are ideal for large-scale applications with ample installation space and higher flow demands, while vertical fire pumps are suited for space-constrained environments and lower flow applications. Learning these differences will help you select the most appropriate fire pump type to ensure effective and reliable fire protection for your facility.

Post time: Sep-04-2024