Water pumps are essential components in various industries, facilitating the movement of fluids for numerous applications. Among the many types of pumps, end suction pumps and multistage pumps are two popular choices, each serving distinct purposes. Understanding their differences is crucial for selecting the right pump for specific applications.

End Suction Centrifugal Pump: Basic Characteristics

End suction pump is a type of centrifugal pump characterized by their single-stage design. In these pumps, the fluid enters at the end of the pump casing and is directed to the impeller, where it is accelerated and discharged. The simplicity of this design makes end suction centrifugal pumps ideal for applications requiring moderate flow rates and pressure.

These end suction centrifugal pumps are commonly used in a variety of settings, including water supply, irrigation, and industrial processes. They excel in transferring clean water and other non-viscous fluids. Due to their straightforward design, end suction centrifugal pumps are relatively easy to maintain and operate, making them a popular choice for many users.

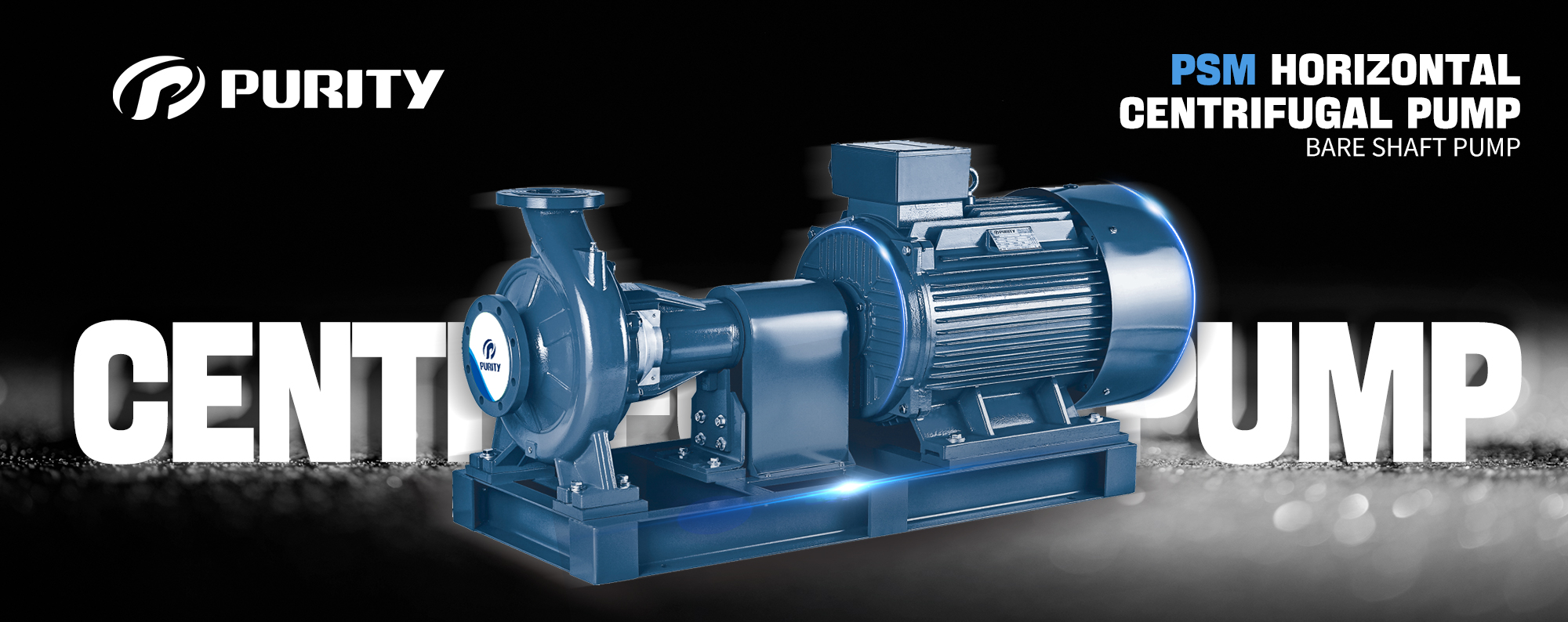

Figure| Purity End Suction Pump PSM

Figure| Purity End Suction Pump PSM

Multistage Pump: Advanced Functionality

Multistage pumps consist of multiple impellers arranged in series, allowing them to generate higher pressure and flow rates. Each impeller adds energy to the fluid, making multistage pumps highly efficient for applications requiring significant pressure increases over long distances.

Multistage pumps are often employed in water supply systems, irrigation, and industrial processes where high pressure is essential. They are also crucial in fire protection systems and HVAC applications, where maintaining adequate pressure is vital for effective operation. The ability to handle varying flow rates and pressures makes multistage pumps versatile in meeting specific operational demands.

Key Differences Between End Suction Centrifugal Pump and Multistage Pump

1.Design and Construction

The most notable difference between end suction centrifugal pump and multistage pump lies in their design. End suction centrifugal pump has a single impeller and is simpler in construction, while multistage pump features multiple impellers, making it more complex.

2.Pressure and Flow Capacity

End suction centrifugal pump typically provides moderate pressure and flow rates, suitable for applications that do not require high energy output. In contrast, multistage pump can achieve significantly higher pressures and are ideal for applications demanding increased energy, such as long-distance water transport and high-rise building water supply.

3.Applications

End suction centrifugal pump is commonly used in situations where fluid movement is straightforward, such as irrigation and water distribution in municipal systems. Multistage pump, on the other hand, is favored in applications requiring high pressure, such as fire protection systems, high-rise buildings, and industrial processes.

4.Efficiency

Multistage pump is generally more efficient in applications where high pressure is necessary. The multiple impellers in a multistage pump enable it to maintain efficiency across varying flow conditions, while end suction centrifugal pump may experience efficiency losses under similar conditions.

5.Maintenance

Due to their simpler design, end suction centrifugal pump is often easier to maintain than multistage pump. The complexity of multistage pump may require more specialized knowledge for maintenance and repair, although its robust design often results in a longer operational life.

Purity Multistage Pump Has Unique Advantages

Compared with other vertical multistage pumps in the same industry,Purity multistage centrifugal pump has the following unique advantages:

1. Full electric protection: prevent collision during production and protect stator coil.

2. Long-lasting and durable: long bearing life, low noise, energy saving.

3. Good heat dissipation effect: full contact between the core and the casing, good heat dissipation effect, low operating temperature rise.

Figure| Purity Vertical Multistage Pump PVT/PVS

Figure| Purity Vertical Multistage Pump PVT/PVS

Summary

Both end suction pumps and multistage pumps play vital roles in fluid handling across various industries. While end suction pumps are ideal for straightforward applications requiring moderate pressure, multistage pumps excel in situations where high pressure and flow rates are necessary.Purity pump has significant advantages among its peers, and we hope to become your first choice. If you are interested, please contact us.

Post time: Oct-24-2024