In the realm of fire safety, selecting the right fire pump is critical to ensure the reliability and efficiency of the fire protection system. Two primary types of fire pumps dominate the industry: electric fire pumps and diesel fire pumps, each with its own set of advantages and disadvantages. This comparative analysis aims to shed light on the key features of both types, guiding facility managers and safety professionals in making informed decisions tailored to their specific needs.

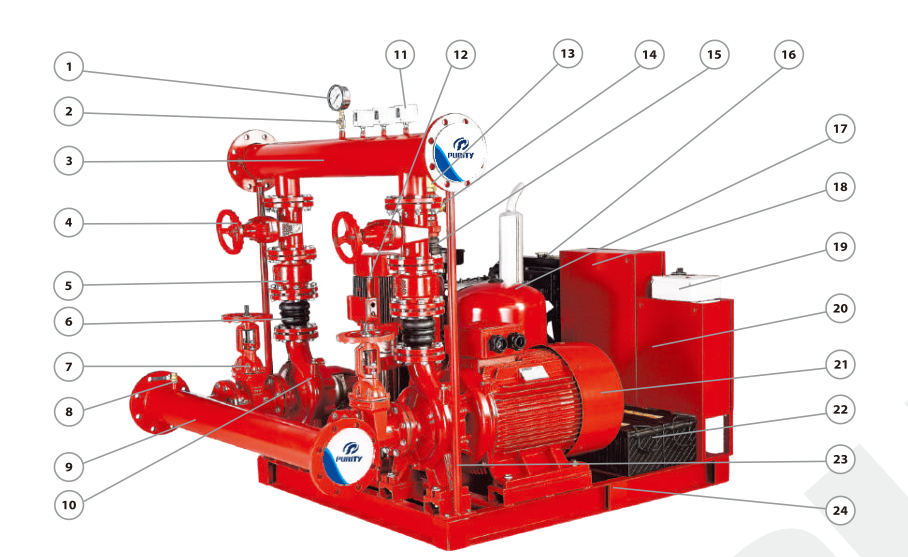

PEDJ Series Diesel Fire Pump

Electric Fire Pumps: The Reliable and Predictable Choice

Electric fire pumps are powered by simple electric motors, capable of operating for thousands of hours without major issues. These pumps are known for their reliability and ease of maintenance. Their design as constant-speed pumps ensures a consistent discharge pressure, eliminating the need for additional pressure safety valves. Moreover, electric motors and controllers can be designed to be explosion-proof, making them suitable for hazardous environments.

However, their reliance on a stable power supply poses a significant drawback. In the event of a power outage, electric fire pumps may become inoperable, necessitating the installation of backup power systems. Additionally, larger electric fire pumps have limitations on the number of starts per hour, which can lead to motor insulation deterioration or controller failure if exceeded.

Diesel Fire Pumps: The Self-Sufficient and Durable

On the other hand, diesel fire pumps offer a level of self-sufficiency that electric pumps cannot match. They can operate independently of the power grid for a limited time, relying on stored energy in the engine’s batteries. This resilience is crucial in scenarios where the main power supply is compromised.

Despite their self-reliance, diesel fire pumps come with higher maintenance requirements and installation costs. The need to manage fuel tanks, exhaust systems, ventilation, cooling lines, and pressure safety valves adds to the complexity and expense of the system. Furthermore, diesel fire pumps require more space in pump rooms due to their additional components. An increase in speed leads to a significant rise in discharge pressure, potentially damaging the fire water network. This necessitates regular checks and calibration of pressure safety valves. Lastly, diesel fire pumps are not explosion-proof, limiting their use in explosive environments.

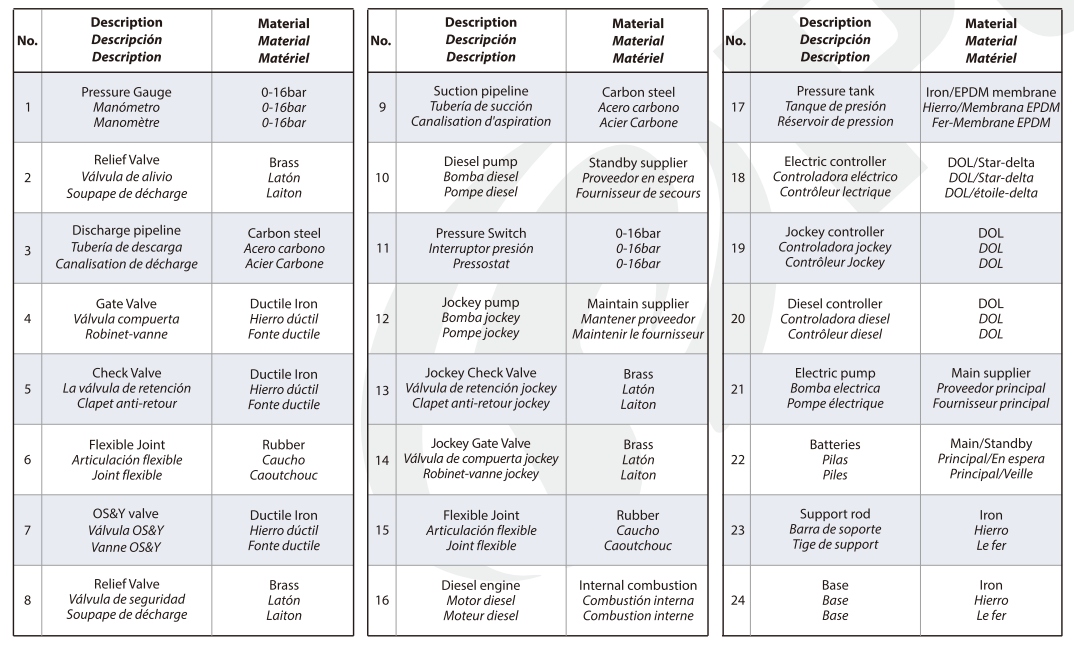

Diesel Pump Component

Choosing the Right Fire Pump for Your Application

The choice between electric and diesel fire pumps should be based on a thorough evaluation of factors including power availability, maintenance capabilities, cost, and environmental conditions. Electric fire pumps are well-suited for environments where a stable power supply can be guaranteed and where space and maintenance are not significant concerns. Diesel fire pumps, on the other hand, are ideal for facilities requiring a more robust and self-sufficient solution, especially in areas prone to power outages or with limited access to electricity.

As facility managers and safety professionals navigate the complexities of fire protection systems, understanding the advantages and disadvantages of electric versus diesel fire pumps is essential. By carefully considering the specific needs and conditions of their facilities, they can make informed decisions, ensuring the safety and well-being of their occupants and assets.

Post time: Aug-07-2024