New Fire Hydrant Pump Enhances Industrial and High-Rise Safety

In a significant advancement for industrial and high-rise safety, the latest fire hydrant pump technology promises to deliver exceptional performance and reliability in firefighting systems. Comprising multiple centrifugal impellers, volutes, delivery pipes, drive shafts, pump bases, and motors, these pumps are engineered to tackle a broad range of fire suppression needs.

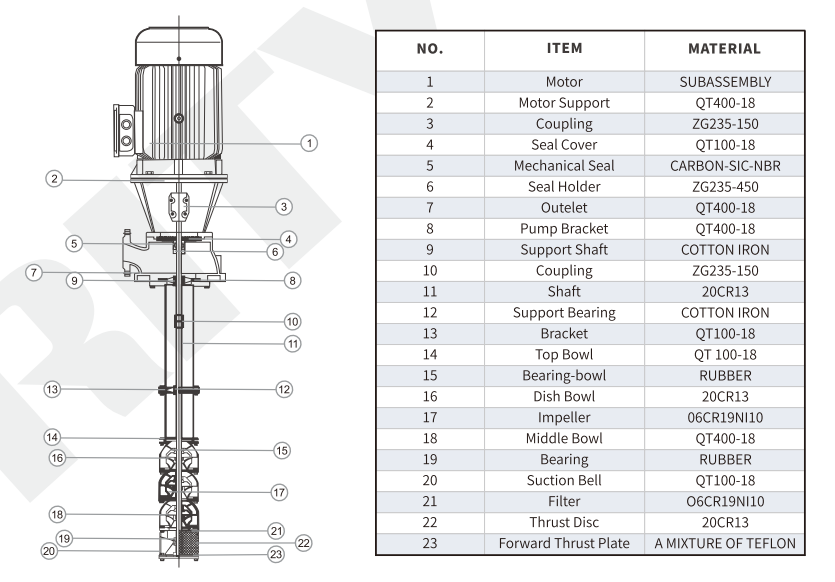

key Components Operation

The fire hydrant pump system is robustly designed with critical components including the pump base and motor, which are positioned above the water reservoir. Power is transmitted from the motor to the impeller shaft through a concentric drive shaft connected to the delivery pipe. This setup ensures the generation of significant flow and pressure, essential for effective firefighting.

1.Working Section

The working section of the pump consists of several key parts: the volute, impeller, cone sleeve, casing bearings, and impeller shaft. The impeller features a closed design, which is crucial for maintaining high efficiency and durability. The casing components are securely bolted together, and both the volute and impeller can be equipped with wear-resistant rings to extend their operational life.

2.Delivery Pipe Section

This section includes the delivery pipe, drive shaft, couplings, and supporting components. The delivery pipe is connected via flanges or threaded joints. The drive shaft is made from either 2Cr13 steel or stainless steel. In cases where the drive shaft bearings experience wear, threaded connections allow for the replacement of short delivery pipes, making maintenance straightforward. For flange connections, simply swapping the direction of the drive shaft can restore functionality. Additionally, a specialized locking ring at the connection between the pump base and the delivery pipe prevents accidental detachment.

3.Wellhead Section

The wellhead section features the pump base, a dedicated electric motor, motor shaft, and couplings. Optional accessories include an electrical control box, short outlet pipe, intake and exhaust valves, pressure gauges, check valves, gate valves, and flexible joints made from rubber or stainless steel. These components enhance the pump’s versatility and ease of use in various firefighting scenarios.

Applications and Benefits

Fire hydrant pumps are primarily employed in fixed firefighting systems for industrial enterprises, construction projects, and high-rise buildings. They are capable of delivering clear water and fluids with similar chemical properties, making them suitable for a wide range of applications. These pumps are also utilized in communal water supply systems, municipal water supply and drainage, and other essential services.

Fire Hydrant Pumps: Essential Usage Conditions

Ensuring the optimal performance and longevity of deep-well fire pumps involves adhering to specific usage conditions, particularly concerning power supply and water quality. Here are the detailed requirements:

1.Rated Frequency and Voltage: The fire system requires a rated frequency of 50 Hz, and the motor’s rated voltage should be maintained at 380±5% volts for a three-phase AC power supply.

2.Transformer Load: The transformer load power should not exceed 75% of its capacity.

3.Distance from Transformer to Wellhead: When the transformer is located far from the wellhead, the voltage drop in the transmission line must be considered. For motors with a power rating greater than 45 KW, the distance between the transformer and the wellhead should not exceed 20 meters. If the distance is greater than 20 meters, the transmission line specifications should be two levels higher than the distribution cable specifications to account for the voltage drop.

Water Quality Requirements

1.Non-Corrosive Water: The water used should be generally non-corrosive.

2.Solid Content: The solid content in the water (by weight) should not exceed 0.01%.

3.pH Value: The water’s pH value should be within the range of 6.5 to 8.5.

4.Hydrogen Sulfide Content: The hydrogen sulfide content should not exceed 1.5 mg/L.

5.Water Temperature: The water temperature should not be higher than 40°C.

Adhering to these conditions is crucial for maintaining the efficiency and durability of fire hydrant pumps. By ensuring proper power supply and water quality, users can optimize the performance and extend the lifespan of their fire pump systems, thereby enhancing the reliability and safety of their fire protection infrastructure.

How does a fire hydrant pump system work?

Fire hydrant pump increases the pressure in a hydrant system when municipal pressure is insufficient or the hydrants are tank-fed.Thereby it enhances the building’s firefighting capability. Normally,the water in the hydrant system is pressurized and ready for emergency use. When firefighters open the hydrant pump, the water pressure drops, which triggers a pressure switch to activate the booster pump.

A fire hydrant pump is essential when the water supply is insufficient to meet the flow and pressure needs of the fire suppression system. However, if the water supply already meets the required pressure and flow, the fire hydrant pump is not needed.

In summary, fire hydrant pump is necessary only when there is a shortage in water flow and pressure.

Post time: Aug-03-2024