Fire protection systems are essential for safeguarding lives and property from the devastating impact of fires. A critical component in these systems is the jockey pump. Though small in size, this pump plays a significant role in maintaining system pressure and ensuring that the system is always ready to respond in case of an emergency. In this article, we will explore the working principles, applications, and importance of jockey pumps in fire protection systems.

1. The Role of a Jockey Pump

The primary function of a jockey pump is to maintain the pressure within the fire protection system by compensating for small leaks and pressure drops. Unlike the main fire pump, which handles the bulk of the water flow during an emergency, jockey pumps have low flow rates but operate at higher pressures. When system pressure falls slightly due to leaks, the jockey pump quickly activates to restore pressure and then shuts off automatically once the correct pressure is reached. This quick response prevents the main fire pump from starting unnecessarily, thereby reducing wear and tear on the system.

Figure | Purity Jockey Pump-PV

2. How Does a Jockey Pump Work?

A jockey pump is equipped with sensors that monitor the pressure within the fire sprinkler or hydrant network. When the system’s pressure drops below a pre-set level, the jockey pump activates to restore the pressure to the desired setting, ensuring the system is always primed and ready for immediate use.

Jockey pumps typically share the same electrical control panel as the main fire pump, allowing for both manual and automatic operation. Additionally, they often include indicators for tracking the number of times they start and stop, which can help identify potential system leaks. If the jockey pump is frequently cycling on and off, it might signal a persistent leak that requires investigation.

3. Applications of Jockey Pumps

According to NFPA 20 standards, jockey pumps are used in fire protection systems where high water pressure needs to be maintained. This is especially important in high-rise buildings, large commercial facilities, and industrial sites, where stable water pressure is crucial for proper system operation. In these settings, jockey pumps help prevent pressure fluctuations that could lead to water hammer, a damaging shock wave caused by sudden changes in water flow. By keeping pressure consistent, jockey pumps contribute to the longevity and reliability of the entire fire protection system.

4. Sizing a Jockey Pump Correctly

Proper sizing of a jockey pump is critical for its effectiveness. The pump should be able to compensate for minor water losses in the fire protection system while maintaining the necessary pressure. For systems with above-ground piping, the pump’s flow rate should be less than the flow rate of a single sprinkler head. For systems with underground mains, the jockey pump should make up for allowable leakage at a rate of either 1 gallon per minute (GPM) or within 10 minutes, whichever is larger.

A good rule of thumb is to size the jockey pump at about 1% of the rated capacity of the main fire pump, with a discharge pressure at least 10 PSI higher than that of the main pump. This ensures that the jockey pump can handle minor pressure drops without triggering the main fire pump, which is reserved for actual emergencies.

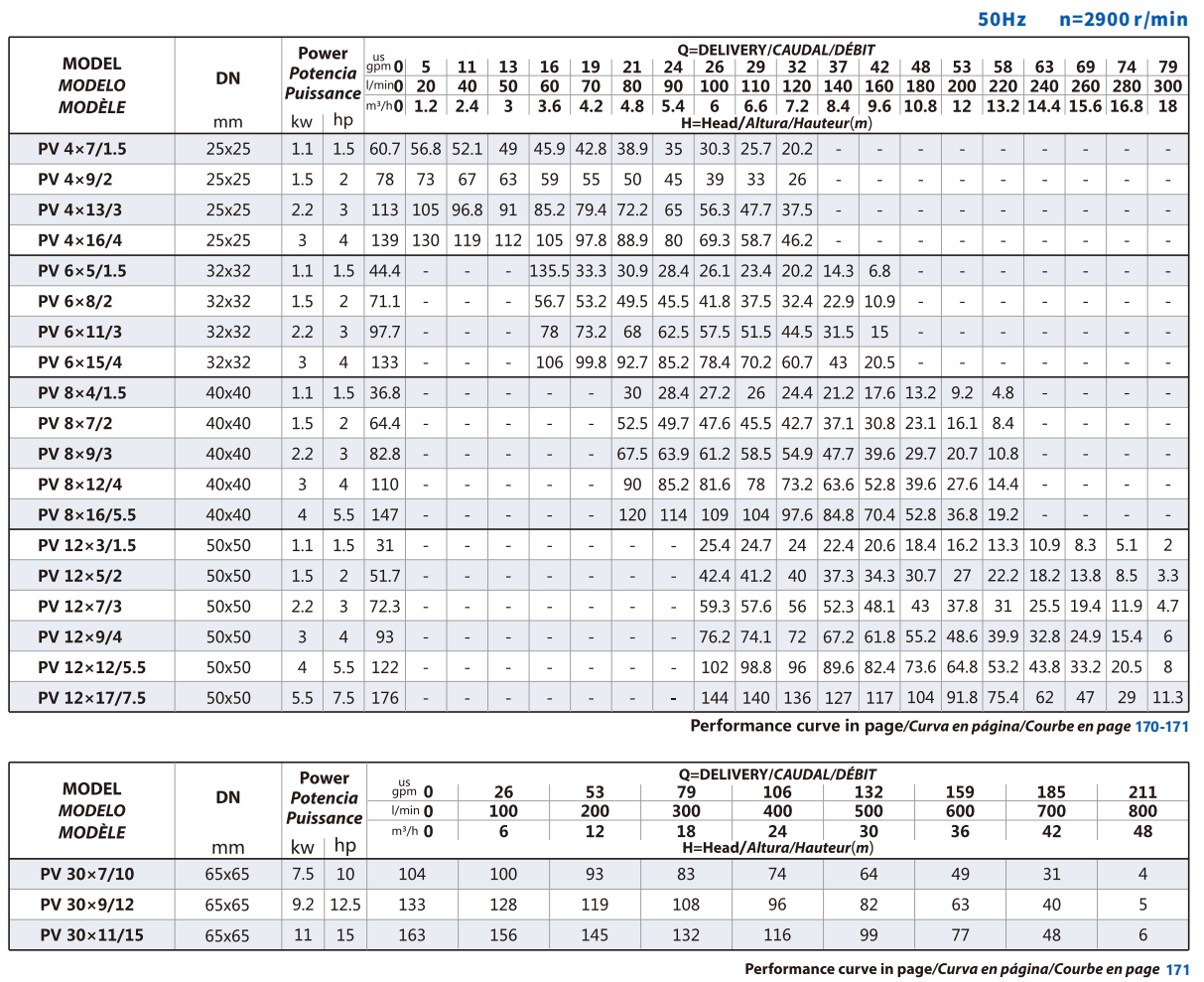

Figure | Purity Jockey Pump PV Parameter

5. The Importance of Jockey Pumps

The importance of jockey pumps in fire protection systems cannot be overstated. They ensure that the system remains pressurized and ready to respond effectively in an emergency. Whether the system is idle or active, the jockey pump plays a critical role in maintaining the necessary pressure.

Frequent activation of the jockey pump may indicate a leak in the system, which should be addressed immediately. In the event of a fire, when the sprinkler or hydrant network is triggered, both the main fire pump and the jockey pump work together to ensure that the system maintains adequate pressure to combat the fire.

6. Unique Advantages of the Purity Jockey Pump

The Purity jockey pump offers several key advantages that set it apart from others in the market:

1. Efficient Hydraulics: The pump is designed with an excellent hydraulic model, making it energy-efficient and ensuring smooth operation.

2. Durable Bearings: It features wear-resistant mechanical seals and bearings, ensuring long service life and preventing leaks.

In conclusion, jockey pumps are essential for the optimal operation of fire protection systems. They maintain system pressure, prevent unnecessary activation of the main fire pump, and ensure that the system is always ready to respond in an emergency. By understanding their role, operation, and importance, we can better appreciate the crucial function they serve in protecting both lives and property. With the unique advantages of the Purity jockey pump, we aim to be your top choice. Contact us today to learn more about how we can meet your fire protection needs.

Post time: Jul-03-2024