Double suction split case pumps are the workhorses of industrial and municipal applications. Renowned for their durability, efficiency, and reliability, these pumps play a critical role in various sectors despite being more expensive and less flexible than some other pump types like end-suction or vertical inline pumps. This article explores the design features and advantages of double suction split case pumps, highlighting why they are the preferred choice for many demanding applications.

Durability, Efficiency, and Reliability

At the core of a double suction split case pump‘s appeal is its exceptional durability. When properly installed, designed, and operated, these pumps can provide decades of service with minimal maintenance. Their robust construction and thoughtful design make them ideal for heavy-duty applications where reliability is paramount. This longevity translates into cost savings over the pump’s lifecycle, offsetting the initial higher investment.

Efficiency is another key attribute of double suction split case pumps. These pumps are designed to handle large volumes of fluid with high efficiency, reducing energy consumption and operating costs. Their unique design minimizes hydraulic losses and maximizes performance, making them an economical choice for continuous operation in industrial and municipal settings.

Reliability is perhaps the most critical factor in the selection of pumps for essential services like municipal water supply and industrial processes. Double suction split case pumps are known for their dependable performance. Their design ensures consistent operation, even under challenging conditions, which is why they are trusted in applications where downtime is not an option.

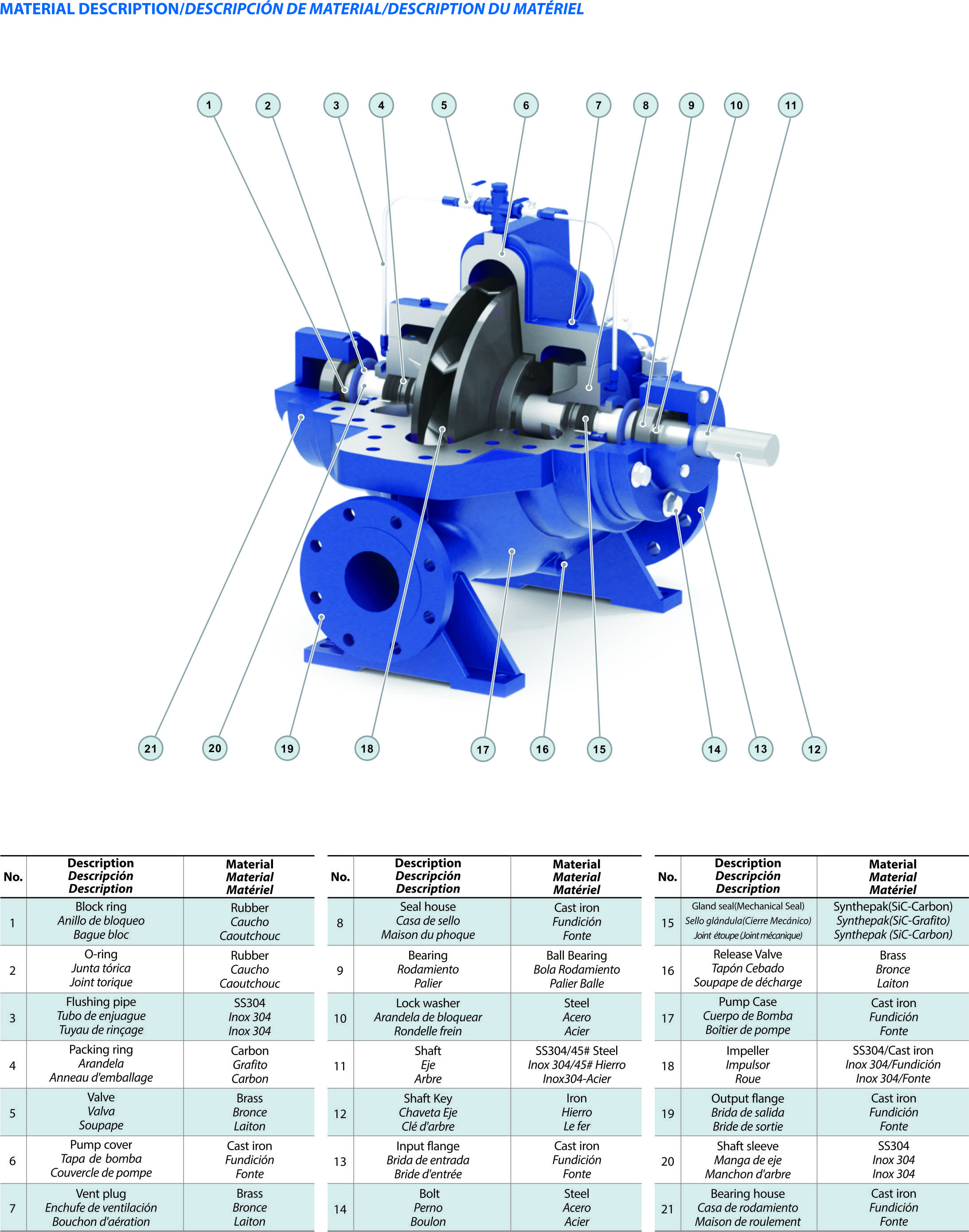

Picture|Purity Double Suction Split Case Pump—PSC

Design Features of Double Suction Split Case Pumps

Axially-Split Design

Most double suction split case pumps feature an axially-split design, meaning that the pump casing is split along the same plane as the pump axis. This design allows for easy access to the internal components of the pump, simplifying maintenance and reducing downtime. The axially-split casing can be opened without disturbing the alignment of the pump or the piping, making inspections and repairs more straightforward and less time-consuming.

Horizontal Mounting

Double suction split case pumps are typically mounted horizontally, a configuration that offers several advantages. Horizontal mounting facilitates easier installation and alignment compared to vertical configurations. It also allows for a more compact and stable setup, which is beneficial in environments where space is at a premium. Although vertical mounting is possible, it is less common and can present safety concerns if not properly engineered.

Double Suction Impeller

A distinguishing feature of double suction split case pumps is their double suction impeller. This design element sets them apart from other common pump types, which usually feature single suction impellers. A double suction impeller draws fluid into the pump from both sides of the impeller, balancing the hydraulic forces and significantly reducing the load on the bearings. This balanced design reduces wear and tear on the pump components, extending the pump’s service life and enhancing its reliability.

Picture|Purity PSC Component

Advantages in Industrial and Municipal Applications

Load Balancing and Maintenance Ease

The balanced design of double suction split case pumps, with their between-the-bearings configuration and double suction impellers, results in fewer loads on the bearings and other critical components. This balanced load distribution minimizes the mechanical stresses on the pump, reducing the likelihood of failures and the need for frequent maintenance. When maintenance is required, the axially-split casing design allows for quick and easy access to the pump internals, minimizing downtime and associated costs.

Versatility and Robustness

Double suction split case pumps are incredibly versatile and robust, capable of handling a wide range of fluids and operating conditions. They are widely used in municipal water supply systems, where their reliability and efficiency ensure a consistent and safe water supply. In industrial applications, these pumps handle various fluids, including those used in manufacturing processes, cooling systems, and other critical operations. The oil and gas industry also relies on double suction split case pumps for their ability to handle high pressures and flow rates, while the mining industry values their durability and performance in harsh environments.

Conclusion

In conclusion, double suction split case pumps are a testament to engineering excellence, combining durability, efficiency, and reliability in a design that has stood the test of time. Their unique features, including the axially-split casing, horizontal mounting, and double suction impeller, make them an ideal choice for demanding industrial and municipal applications. With balanced load distribution and ease of maintenance, these pumps offer significant advantages in terms of longevity and operational efficiency. Whether in municipal water systems, industrial processes, oil and gas operations, or mining applications, double suction split case pumps continue to be the dependable workhorses that industry professionals rely on.

Post time: Jun-14-2024