Each of the 360 industries has its own patents. Applying for patents can not only protect intellectual property rights, but also enhance corporate strength and protect products in terms of technology and appearance to enhance competitiveness. So what patents does the water pump industry have? Let’s go explore it together.

1.Pump based control system

Generally speaking, water pumps cannot independently adjust the speed to control the flow. An intelligent control system is required to change the current frequency and adjust the pump speed to control the water pump flow, so as to save energy, reduce power consumption and reduce environmental pollution. The water pump under intelligent control will not affect the water supply pipeline, and naturally it will not affect the water use of other users.

Figure | Intelligent frequency conversion water pump

Figure | Intelligent frequency conversion water pump

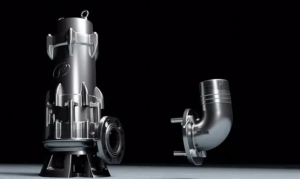

2.A highly sealed water pump

The water pump is operated by electricity. Whether it is used indoors or outdoors, the waterproof and leakage-proof function is an extremely important part. In addition, the water pump is a high-speed machine, and particulate matter is not allowed to enter during operation, otherwise it will cause wear and tear of parts and greatly reduce the service life of the water pump.

Currently, the highest waterproof and dustproof level is IP88. Water pumps at this level can completely prevent water and dust from entering. This is the waterproof level that submersible pumps must reach. For water pumps that do not require submersible operations, it only needs to be able to adapt to the impact of high-pressure water columns to prevent dust intrusion. The sealing performance of the water pump can be improved by optimizing the parts and pump body structure to achieve comprehensive dustproof and waterproof effects.

Figure| PZQ waterproof energy-saving self-priming pump

Figure| PZQ waterproof energy-saving self-priming pump

3.A multi-purpose flange water pump

The flange is the part that connects the water inlet and outlet pipes of the water pump. The flange size has a relatively unified international standard. Generally speaking, the interface conversion between flanges of different sizes cannot be carried out. However, by optimizing the design and adjusting the flange process, a multi-purpose flange can be produced. The flange can adapt to a variety of interfaces of different sizes, making the water pump more applicable and avoiding the cost of replacing flange interfaces. Spending reduces unnecessary waste of resources. For example, the flange interface on Purity‘s WQ sewage pump series is suitable for flange sizes such as PN6/PN10/PN16, avoiding the trouble of replacing flanges.

As the largest consumer and producer of water pumps, my country’s huge market continues to promote the development of water pump technology. The same technological progress also delivers a steady stream of new products to the water pump market. We can learn about water pumps through patents in the water pump industry. Technology development and product research and development trends, and ultimately achieve the purpose of understanding the water pump industry.

Figure |Multi-purpose flange structure

Figure |Multi-purpose flange structure

The above is the entire content of this article. Follow Purity Pump Industry to learn more about water pumps.

Post time: Oct-09-2023