There are many classifications of water pumps, different classifications of pumps correspond to different uses, and the same type of pumps also have different models, performance and configurations, so it is very important to choose the type of pumps and the model selection.

Figure | Large pumping station system

How exactly should you choose a pump?

Water pump has a hundred billion market, there will be a lot of uneven quality pumps on the market, unreasonable pump selection will make the pump in abnormal operation, when the pump does not meet the requirements of the pump station system design, which will directly affect the reliability of the pump, service life, maintenance, parts damage, performance play, etc., the most intuitive consequences of wrong selection is [more money] [low efficiency] [labor].

Figure | Pumps for agricultural irrigation

Don’t think it’s hard!!! Water pump selection, two moves to get. (The end and then send the dregs of a trick Oh ~)

The first move: highlighting

To meet the production process design requirements, in line with the premise of the production process design requirements, go for a wide range of applications, the pump body structure is simple, which is conducive to reducing maintenance costs, improve service life and reduce the cost of parts replacement.

Figure | Indoor pumping station

Secind trick:confirm the elements

1. Application environment Including ambient temperature, relative humidity, explosion-proof requirements, dustproof and waterproof requirements.

2. Liquid properties Liquid type, temperature, density, viscosity, the presence of solid particles, corrosiveness, volatility, flammability, toxicity, etc.

3. Overflow accessories With or without health, heat resistance, corrosion resistance, wear resistance and other requirements .

4. selected pump performance parameters Flow rate: It is directly related to the production capacity and conveying capacity of the whole device. Head: Generally, the head should be selected by enlarging the head after 5%-10% margin. Power: Generally, the pump with power form and size by the production plant optional. Cavitation margin: check the pump device cavitation margin, must cavitation margin is matched.

5. determine the pump installation type According to the pipeline layout, installation site selection of horizontal, direct connection, vertical and other types.

6. determine the number of pumps and spare rate Determine the number of pumps required for normal operation and the need for standby pumps and the number of pumps.

The third move: the dregs of the blind selection

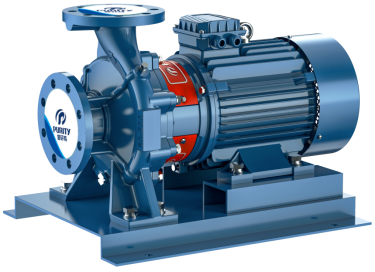

Figure | Pipeline Pumps

Generally speaking, the structure of pipeline pumps is simpler than other pumps, and the application range is more extensive, if you really do not know how to choose, you can blindly choose a pipeline pump.

Summary: After reading these three moves, I believe we have a certain understanding of how to select the pump, have other questions, you can leave a message to discuss it.

Post time: Jul-21-2023