Pre-Statup: Filling the Pump Casing

Before a single stage centrifugal pump is started, it is crucial that the pump casing is filled with the liquid it is designed to transport. This step is essential because centrifugal water pump cannot generate the suction necessary to draw fluid into the pump if the casing is empty or filled with air. Priming the single stage centrifugal pump, or filling it with liquid, ensures that the system is ready for operation. Without this, the centrifugal water pump would be unable to create the required flow, and the impeller could be damaged by cavitation—a phenomenon where vapor bubbles form and collapse within the liquid, potentially causing significant wear to the pump components.

Figure| Purity Single Stage Centrifugal Pump PSM

The Role of the Impeller in Fluid Movement

Once the single stage centrifugal pump is properly primed, the operation begins when the impeller—a rotating component within the pump—starts to spin. The impeller is driven by a motor through a shaft, causing it to rotate at high speeds. As the impeller blades spin, the liquid trapped between them is also forced to rotate. This movement imparts centrifugal force to the liquid, which is a fundamental aspect of the pump’s operation.

Centrifugal force pushes the liquid from the center of the impeller (known as the eye) towards the outer edge or periphery. As the liquid is propelled outward, it gains kinetic energy. This energy is what enables the liquid to move at high velocity from the impeller’s outer edge into the pump’s volute, a spiral-shaped chamber that surrounds the impeller.

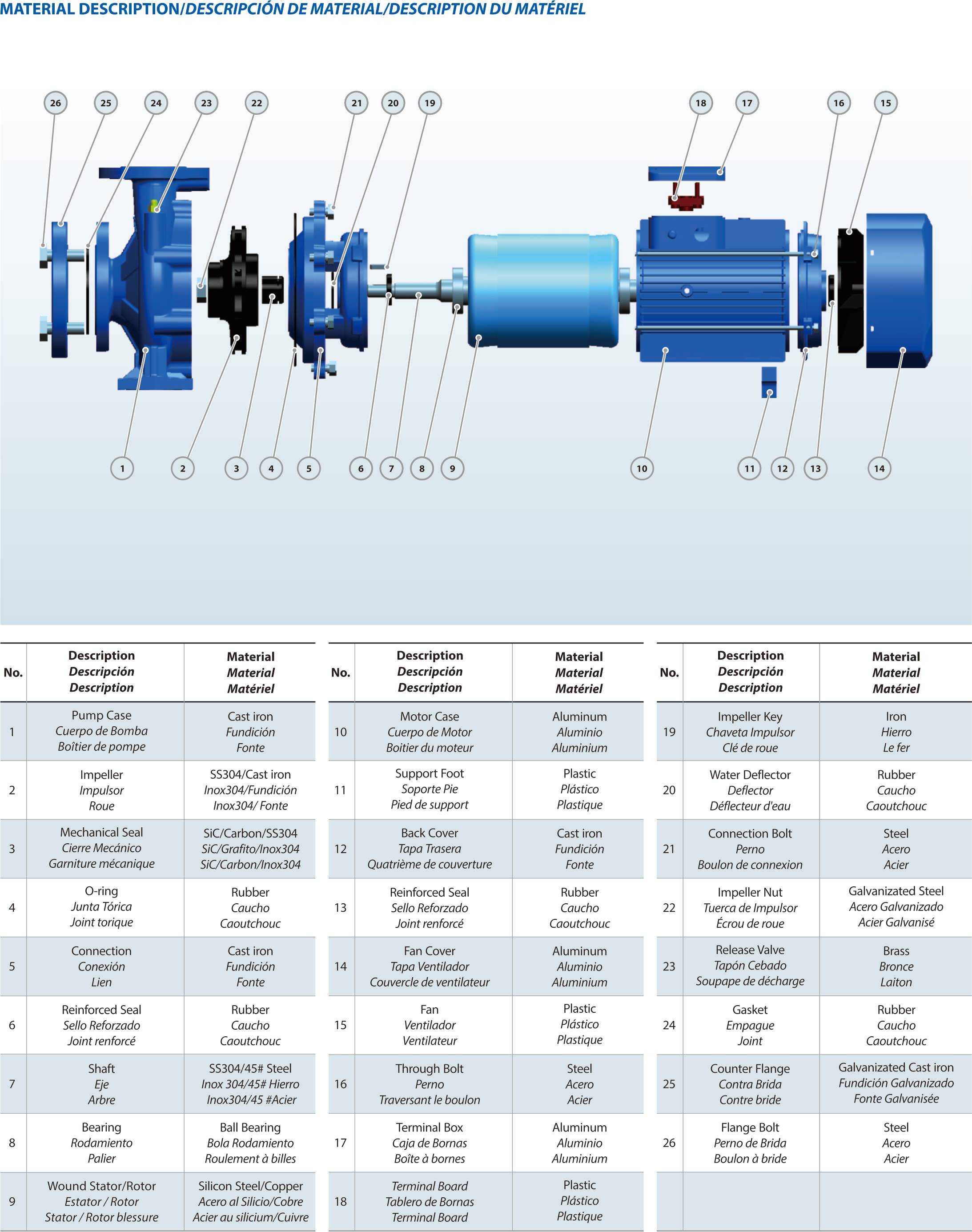

Figure| Purity Single Stage Centrifugal Pump PSM Components

The Transformation of Energy: From Kinetic to Pressure

As the high-speed liquid enters the volute, its velocity begins to decrease due to the expanding shape of the chamber. The volute is designed to slow down the liquid gradually,which leads to the conversion of some of the kinetic energy into pressure energy. This increase in pressure is critical because it allows the liquid to be pushed out of the pump at a higher pressure than it entered, making it possible to transport the liquid through discharge pipes to its intended destination.

This process of energy conversion is one of the key reasons why centrifugal water pumps are so effective at moving liquids over long distances or to high elevations. The smooth transformation of kinetic energy into pressure ensures that the centrifugal water pump operates efficiently, minimizing energy losses and reducing the overall operational cost.

Continuous Operation: The Importance of Maintaining Flow

A unique aspect of centrifugal water pumps is their ability to create a continuous flow of liquid as long as the impeller is rotating. As the liquid is thrown outward from the center of the impeller, a low-pressure area or partial vacuum is created at the impeller’s eye. This vacuum is critical because it draws more liquid into the pump from the supply source, maintaining a continuous flow.

The differential pressure between the liquid surface in the source tank and the low-pressure region at the impeller’s center drives the liquid into the pump. As long as this pressure difference exists and the impeller continues to rotate, single stage centrifugal pump will keep drawing in and discharging liquid, ensuring a steady and reliable flow.

The Key to Efficiency: Proper Maintenance and Operation

To ensure that a single stage centrifugal pump operates at its peak efficiency, it is important to follow best practices in both operation and maintenance. Regularly checking the pump’s priming system, ensuring that the impeller and volute are free of debris, and monitoring the motor’s performance are all essential steps in maintaining the pump’s efficiency and longevity.

Properly sizing the pump for the intended application is also crucial. Overloading the pump by asking it to move more liquid than it was designed for can lead to excessive wear, reduced efficiency, and ultimately, mechanical failure. On the other hand, underloading a single stage centrifugal pump can cause it to operate inefficiently, leading to unnecessary energy consumption.

Post time: Aug-15-2024