Best Quality Cutting Pump Submersible Household Sewage Pump

Product Introduction

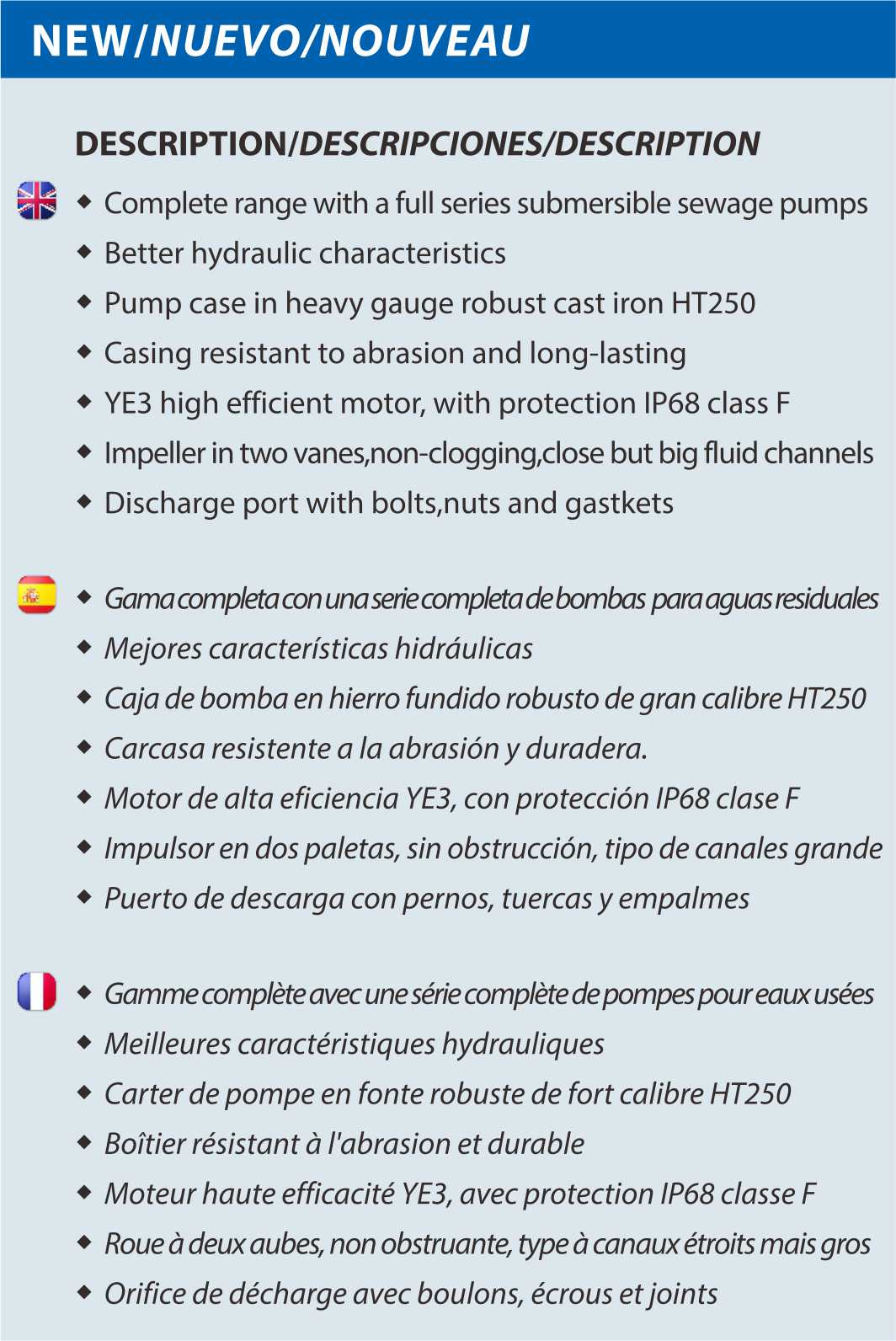

1. Enhanced Durability with 304 Stainless Steel Shafts

A critical feature of the Purity WQA sewage pumps is the use of 304 stainless steel for the shafts. The choice of 304 stainless steel is pivotal in enhancing the durability and longevity of the pumps. Stainless steel is well-known for its exceptional resistance to corrosion, which is especially important in sewage applications where the pump components are frequently exposed to harsh and corrosive environments. The corrosion-resistant properties of 304 stainless steel ensure that the shafts remain intact and functional over extended periods, even when operating in challenging conditions. This not only extends the life of the pump but also reduces maintenance costs and downtime. For users, this means a more reliable pump that can consistently perform without the frequent need for repairs or replacements, ensuring smooth operation and peace of mind.

2. Full-Head Design for Broader Application Range

The Purity WQA sewage pumps feature a full-head design, which significantly expands the range of performance points. This design allows the pumps to maintain optimal performance across a wide range of flow rates and pressures. The full-head capability is crucial in sewage applications, where varying loads and conditions can pose significant challenges. By offering a broader application range, the Purity WQA pumps can accommodate diverse operational requirements without compromising performance. This flexibility helps in preventing issues related to incorrect pump selection, such as motor burnout, which can occur when a pump is forced to operate outside its optimal performance range. With the full-head design, users can be confident that the Purity WQA sewage pumps will handle various conditions efficiently, reducing the risk of operational failures and extending the pump’s service life.

3. Ultra-Wide Voltage Operation for Reliable Performance

The ability of the Purity WQA sewage pumps to operate under an ultra-wide voltage range is another noteworthy innovation. In many regions and applications, power supply stability can be a significant concern. Voltage drops, especially during peak usage periods, can cause substantial problems for electrical equipment, including difficulties in starting and potential damage to the motor. The ultra-wide voltage operation feature of the Purity WQA pumps ensures that they can start and function effectively even when the supply voltage is lower than optimal. This capability is particularly beneficial during peak electricity usage times when voltage drops are most likely to occur. By maintaining reliable operation despite voltage fluctuations, the Purity WQA pumps provide users with consistent performance and protect the equipment from electrical damage. This not only enhances the pump’s reliability but also ensures its longevity, making it a dependable choice for demanding sewage applications.

The Purity WQA series of sewage pumps showcases advanced technological features that address key challenges in durability, versatility, and operational reliability. The use of 304 stainless steel shafts offers superior corrosion resistance, significantly extending the pump’s lifespan and reducing maintenance needs. The full-head design increases the range of applicable performance points, ensuring the pumps can handle various operational scenarios without risk of burnout. Additionally, the ultra-wide voltage operation ensures reliable performance even under fluctuating power conditions, safeguarding the pumps from potential damage and ensuring uninterrupted operation. These innovations make the Purity WQA sewage pumps an excellent choice for users seeking robust, versatile, and reliable solutions for their sewage management needs.